- Home

- Medical Devices and Components

- Laser Processing

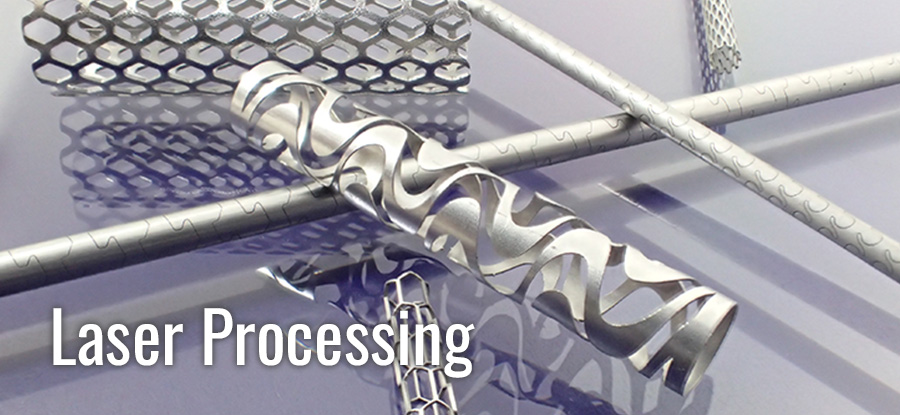

Laser Processing

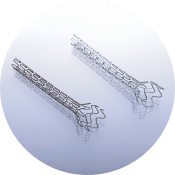

Laser processes for Stents

We use a laser to cut out and expand tube and hypotube into custom patterns and designs. Nitinol material has shape memory, making it possible to realize a variety of shapes.

We collaborate with our overseas group companies to carry out prototyping and mass production.

Overseas group companies

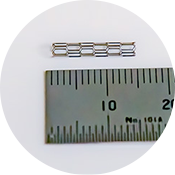

Standard Process Range

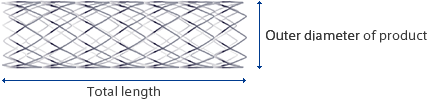

| Outer diameter of pipe | φ0.25㎜~φ19㎜ |

|---|---|

| Outer diameter of product | φ0.05㎜~φ1㎜ |

| Materials | Ni-Ti, SUS, Co-Cr |

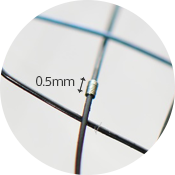

Laser welding

It is possible to weld metal parts of the same type.

Spot diameter: φ0.02mm

Some extra processes

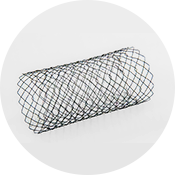

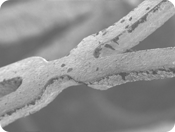

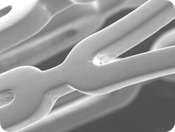

Electropolishing (finishing process)

This is a processing method in which metal is placed in an electrolytic solution and an electric current is passed through it to smooth the metal surface. Burrs and unevenness are removed, and the resulting surface is extremely smooth.

Materials: Nitinol, SUS steel, titanium, etc.

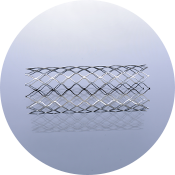

Benefits of electropolishing

The following characteristics make it possible to use it for medical device parts.

- Smoothing treatment (surface roughness (Ra) = up to 0.1 μm)

- Improved durability

Before electropolishing

After electropolishing