- Home

- Medical Devices and Components

- Torque Coils (Multi Strand Multi Layer Coils)

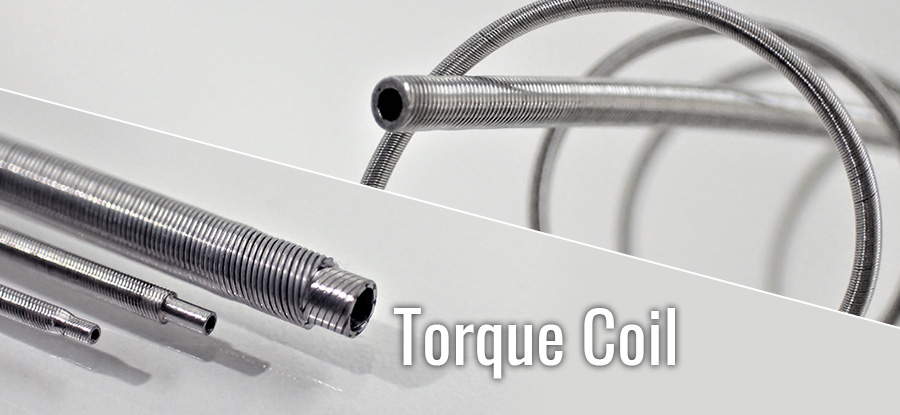

Torque Coils

(Multi Strand Multi Layer Coils)

What is a Torque Coil (Multi Strand Multi Layer Coil)?

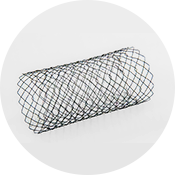

A torque coil (also known as a multi strand multi layer coil) is a coil made by winding several strands of wire as thin as a hair together. The "strand" refers to the number of strands used in coiling, and the rigidity can be changed by changing the number of strands.

It has excellent flexibility and rotational synchronization, and can accurately transmit the rotational motion from one end to the other over long distances. It is used in intravascular imaging devices and endoscopic treatment tools because it exhibits excellent rotational synchronization even in twisted blood vessels and curved areas such as the large intestine. We will propose the optimal number of strands and layers according to the application, and we accept orders from prototypes to mass production, so please feel free to contact us.

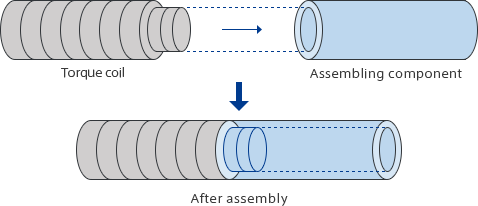

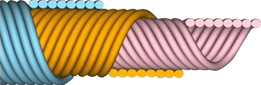

Structure Image

The hollow structure allows wires to be

inserted into the inner diameter of the coil.

Applications

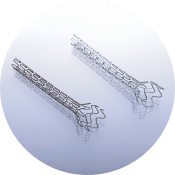

- Intravascular imaging devices (IVUS, OCT, etc.)

- Endoscopic treatment instrument (Forceps, snares, high-frequency knives, high-frequency probes)

- Catheters

Features

Rotational Synchronization (tracking)

When one side of a torque coil (also known as a multi strand multi layer coils) is turned, the tip of the other side rotates evenly. With a normal long coil spring, twisting occurs when it is turned, making it difficult to transmit the rotation, but with a torque coil, the rotation between the handle and the tip is transmitted at a ratio of approximately 1:1.

Rotational Synchronization movie

A coil inserted in a sheath is placed in a hoop shape and rotated by connecting one end to a motor. Even in the twisted hoop state, you can observe that the marks at both ends of the coil rotate synchronously.

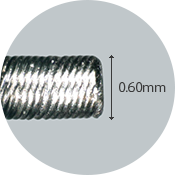

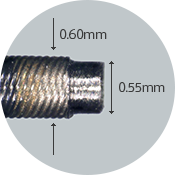

Standard Process Range

We can provide custom-made torque coils from the standard 8-strand 3-layer design, with the number of strands, layers, and wires customized to your needs, from prototypes to mass production. We accept orders for small lots starting from one piece, so they can be used for prototype development. We can also consider specifications outside the listed standards, so please feel free to contact us.

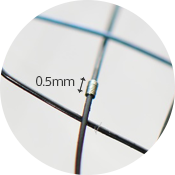

| Strand diameter * | 30μm or more |

|---|---|

| Inner diameter | 0.18mm~9.0mm |

| Outer diameter | 0.3mm~10mm |

| Coil length | 3000mm at maximum |

| Layer | 1~3 |

| Number of strands * | 1~12 |

*The values listed are based on a standard D/d = approximately 6.

The pitch and inner/outer diameters vary depending on conditions such as D (center diameter) ÷ d (wire diameter), so please contact us for more information.

Comparison of round and flat wire

Round wire coil

It has excellent high speed rotation and rotation synchronization.

Wire diameter φ0.05

Wire diameter φ0.05

Flat wire coil

This is suitable when you want to maintain the inner diameter with a thin wall.

Plate width W0.05

Plate width W0.05

| Round wire | Flat wire *1 | |

|---|---|---|

| High speed rotation | ✓✓ | ✓ |

| Flexibility | ✓✓ | ✓ |

| Low elongation *2 | (✓) | ✓ |

*1 Minimum plate thickness: 0.02 mm. Plate thickness: plate width = approx. 1:5

*2 Coil resistance to stretching

Performance comparison between single layer, 2 layer and 3 layer

Example: Outer diameter φ1.0mm priority, Inner diameter φ0.5mm (reference value)

| Single layer | 2 layer | 3 layer | |

|---|---|---|---|

| Strand wire diameter (mm) *1 | φ0.26 | φ0.12 | φ0.08 |

| Outer diameter (mm) | φ1.0 | φ1.0 | φ1.0 |

| Inner diameter (mm) | (φ0.48) | (φ0.52) | (φ0.52) |

| Rotational synchronization | - | ✓ | ✓✓ |

| Flexibility *2 | (✓) | ✓ | ✓✓ |

| Rigidity *2 | ✓✓ | ✓ | - |

| High speed rotation *3 | ✓ | ✓✓ | ✓✓ |

| Cost reduction | ✓✓ | ✓ | (✓) |

| Low elongation *4 | ✓✓ | ✓ | - |

*1 The material is JIS standard size stainless steel wire for springs (SUS304WPB).

*2 Evaluation is based on the amount of dripping.

*3 High speed is defined as 10,000 rpm, while medium and low speeds are defined as 5,000 rpm and 2,000 rpm, respectively.

*4 Refers to the coil's resistance to stretching.

Since flexibility and rigidity are mutually exclusive properties, we customize the number of strands according to your needs and propose the best specifications for you.

Some extra processes

Coil end process

Before grinding

After grinding

Tapering process

Sub-Assemblies process

We also carry out assembly processing of torque coils and other assembly parts.